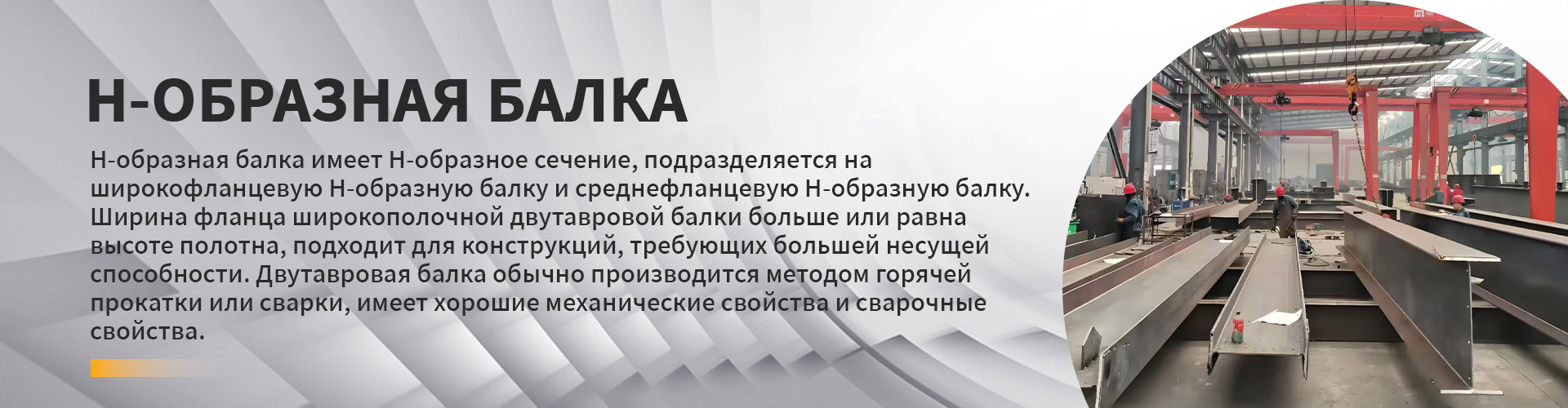

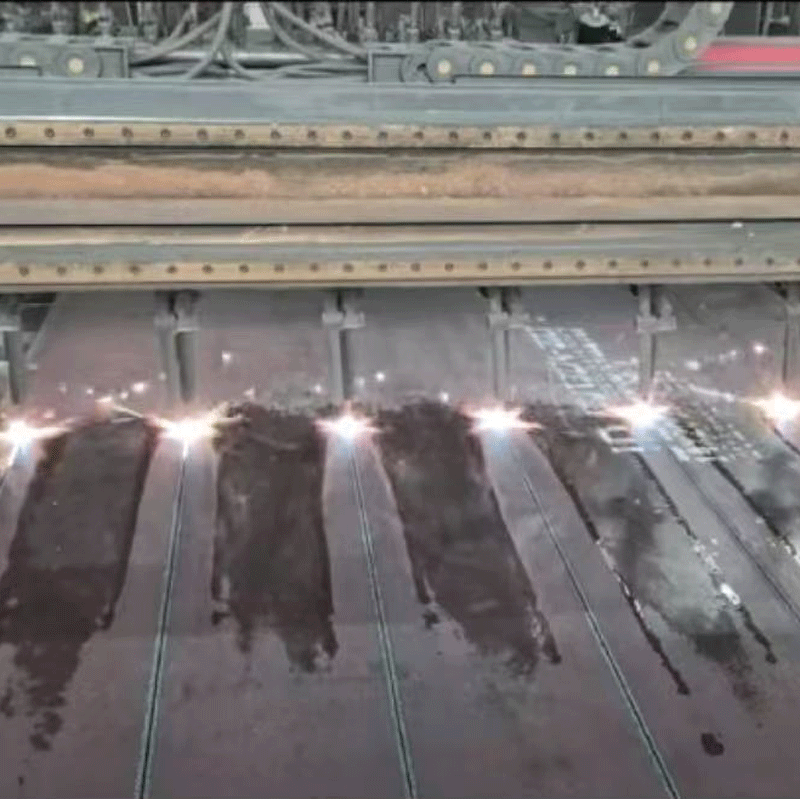

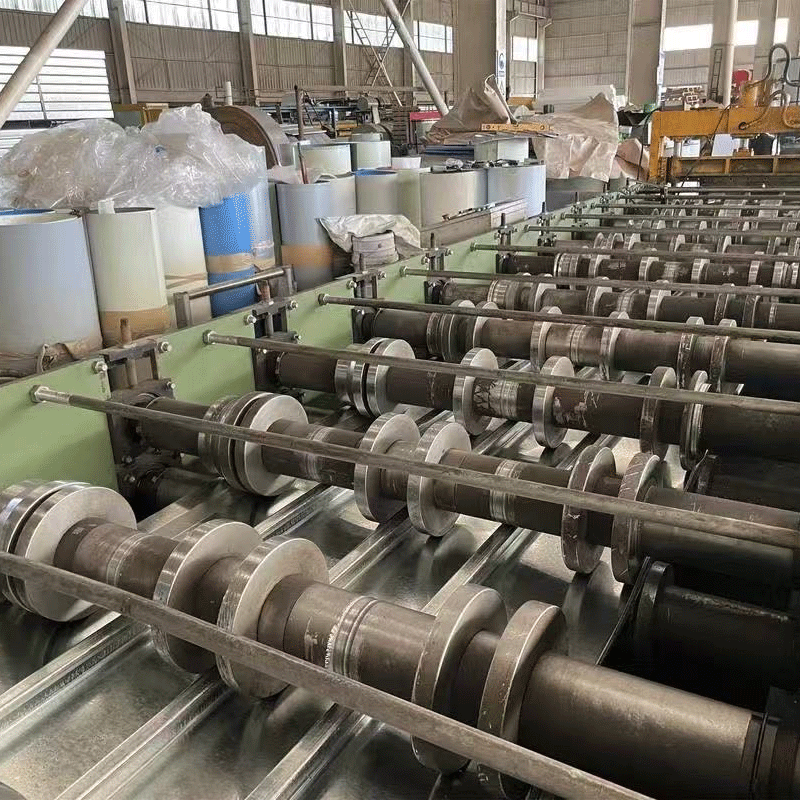

How to improve the quality of steel structure welding process The welding process of steel structure is an important of steel structure engineering. The good and bad welding quality directly affects the service performance and safety of the structure, and even the quality problems of the project. But how to improve quality of steel structure welding process? The quality management of all staff, all-round and the whole process should be implemented throughout the project, which is an effective way to the quality of steel structure welding process. In the management, the control of weld cracks and welding defects should be guided, the training of welders should be based on, and qualified rate of welds should be 100%. The reform of technology should be implemented, and the society should be mobilized to achieve technological progress. For the factors of welding project failure, corresponding countermeasures should be taken. Thus, the quality of steel structure welding process is improved. Steel structure welding mainly includes welding of steel, angle steel, box section and round section. It is divided into workshop welding and site welding. Adopting certain welding process welding parameters is an effective measure to ensure the quality. Workshop welding mainly adopts automatic submerged arc welding and semi-automatic submerged arc welding. The welding quality directly affects the service performance and safety of the welded, and usually adopts the corresponding welding process to weld, select the welding material, welding temperature, reasonable welding sequence and welding method to reduce the welding residual stress, and thus the welding quality. Therefore, workshop welding has a certain quality assurance. To improve the quality of steel structure welding process, it mainly depends on the construction welding on site. Site mainly adopts manual welding and carbon dioxide gas shielded welding. In order to improve the quality of site welding, certain measures should be taken: 1. In terms of design, to design lap welding, and try not to use vertical welding, which is convenient for the operator. 2. In terms of process, it is necessary to operate strictly according to requirements, such as drying welding rod, welding seam cleaning, etc. 3. If the weld grade is high, protection and detection measures should be taken, such as nondestructive testing for Class I and Class II welds on site, and calculation for Class III welds. 4. Do a certain wind protection measures when welding with carbon dioxide shielded welding. At the same time, the quality of the welding directly reflects the technical level of the welder, determines his working ability, and the appearance quality of thed can directly reflect the overall quality of the weld. In welding production, welders often only pay attention to the flaw detection results of the nondestructive testing personnel, and not pay enough attention to the appearance quality of the weld, thus often resulting in the unqualified appearance of the weld and the rework, which reduces the welding quality. can be said that the construction welding on site is greatly affected by the welder. Therefore, find skilled welders, especially when welding important welds, you must choose an and responsible good welder. For the welding process of welders, there are several points of measures and requirements: First, select the appropriate welding flux and welding material elding flux is divided into organic, inorganic and resin three categories. Inorganic welding flux is commonly known as welding oil, which has strong chemical action and strong activity, but is corrosive and usually not used. Organic welding flux also has certain corrosiveness and is generally not used alone. Rosin welding flux is a reliable welding flux, which is widely in circuit maintenance and electronic production. Rosin, when heated, hasCertainly has the ability to clear oxides, and has little corrosion, but rosin has a poor ability remove oxides, and has a weak soldering effect. In order to improve the soldering performance, appropriate amount of activator can be added to the rosin, such as a little glycerol. Second, scraping and soldering The welding components and wires are scraped and soldered. Some wires and components look bright, but in there is still an oxide layer on the surface. After direct welding, the solder covers the leads, and it looks like a closed solder point, but it is likely to a false solder. Third, master the welding time During welding, different welding time should be determined according to different welding objects. For components, if the welding time too long, it will be damaged, and the copper foil on the printed board will be warped. If the time is too short, it will cause insufficient heating, insufficient sold agent, and reduced strength of the solder point, resulting in false soldering. In general, it is appropriate to control the welding time within 2 seconds, and if it wire, metal welding, the time can be relatively long. Fourth, do not use the soldering iron head to carry solder During welding, some people are used using the soldering iron head as a tool to carry solder, which is incorrect. Because manual welding is usually used with soldering paste, if the soldering iron head contacts solder first and is used as a carrying tool, the soldering agent will decompose and volatilize under high temperature, making the welding in a state of no sold agent, which is prone to welding defects. When welding, one hand should hold the soldering iron, and one hand should hold the solder wire, and provide solder while. Fifth, cooling After the soldering iron leaves the solder point, it should be allowed to cool naturally, and it is strictly forbidden to blow with mouth other forced cooling methods, so as to avoid the risk of solder scalding or the position of the welded object changing due to external force. In the work, should attach importance to the establishment and improvement of the quality assurance system for steel structure welding engineering, and do a good job in management and technology. Without effective management, even the best is difficult to achieve; without technology, even the best management is empty talk. The organic combination of the two basic works can ensure the quality of steel structure welding engineering. The concept comprehensive quality, the quality management of the whole process, and the idea of full-staff participation in quality management are indispensable for excellent welding engineering. In addition, an excellent welding should not only reflect the concept of serving the user, the concept of prevention first, the concept of speaking with data, and the principle of planning, execution, inspection, summary and, but also implement the management to personnel, equipment and tools, steel and welding materials, welding process, construction environment, in order to improve the quality of steel structure welding process and the safety of steel structure. Use.

Последние новости